WELCOME TO

FAB PHARMA

Equipped with Ultra-Modern Plant, Infrastructure and skilled manpower. The forte of FAB Pharmaceuticals Pvt. Ltd. lies in Contract Manufacturing.

Despite manufacturing products with its own brand “FAB”, it also assists several companies to produce products under its brand name. Various

products of the company are registered in several countries under this brand name.

During this long journey spanning over a decade, the company has successfully established a reputation as a quality supplier of medical devices in India as well as across the globe.

OUR QUALITY

ASSURANCE & CERTIFICATION

The Quality Control Laboratory has been certified to perform biological, chemical, microbiological, physical, sterility and toxicity tests. The Laboratory

is equipped with state-of-the-art technology and staffed with qualified and trained personnel.

Quality Control System at FAB encompasses a systematic, fully documented, comprehensive and exhaustive series of bacteriological, chemical, physical

and visual tests; with regular inspections at each pertinent stage of production cycle. This involves constant surveillance of raw- materials, intensive in-process

control of all manufactured parts, sub-assemblies and final inspection and testing of finished products.

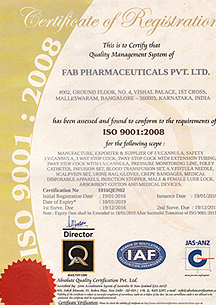

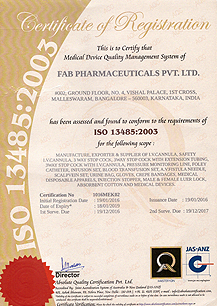

The Company's plant is GMP (Good Manufacturing Practices) Certified and under the aegis of ISO (International Organization for Standardization).

We have successfully installed, implemented

and updated Quality Management Systems. We are also accredited

for ISO 9001:2008, and IS 13485:2003 certifications; and all

products are available with CE marking .

OUR

VISION

FAB's vision is to create world class Health Care Products and emerge to be

a global leader in offering unique and innovative services in Health Care in

the stature of a visionary leader and to ensure stability, efficacy of the health

specialty products are maintained. Managing distribution to meet the

expectations of Clients.

CONTRACT

MANUFACTURING & SERVICES

FAB Pharmaceuticals Pvt Ltd.is a Medical Device manufacturer in India since 2012. It has the largest 30000 Sq. feet manufacturing facility with ISO 9001:2008 & ISO 13485:2003 certifications. The products also have CE marking.

FAB manufactures and offers a wide range of Medical Devices for Infusion Therapy, Transfusion Therapy, Dialysis, Gastroenterology, Urology, Anaesthesia and Surgery. The products include Needle Free Infusion sets, Urine Meters, Blood Lines, and Extension Lines. This offers FAB a straight forward mode to work for OEM.

Contract manufacturing as per customer specifications:

FAB analyzes the project to identify ways to streamline the production process, minimize the costs and delivery time. Whether through improvements in technology or operational enhancements, FAB constantly looks out for ways to improve quality and reduce costs. Customized production is possible for small but frequent short runs, as well as large volume mass productions, makes FAB an ideal partner for outsourcing.

Company's capabilities include

- - R.F Welding, Silk Screen Printing.

- - Clean Room of Class 10,000 and Hygienic premises.

- - Solvent Bonding, Leak Testing, Assembly with jigs and fixtures.

- - Tipping and Punching.

- - Medical Device Packaging including pouch sealing, kit packing.

- - ETO sterilization.

- - In-house laboratory for testing Medical Devices.

- - More than 80% of the company's production is exported to more than 32 countries.

Unrivalled rates compared to other manufacturers:

We offer an enormous range of products to choose from. As we have an all-set infrastructure, our customers can leverage the same without incurring additional charges. We have also invested in regulatory compliance, supply chain management, engineering, manufacturing operations and logistics for

our own products. Our customers can also take advantage of the best quality system, and infrastructure that we demand for our own product,

without paying an extra penny. The Company boasts of a trained team that we trust to design and manufacture our own products. We offer our clients all the

facilities that we use for our products. The rates are unique, because of the available amenities, thus neither the company nor the client has to invest an extra

penny to attain desired results.

Engineering and Prototyping:

The Management of FAB started their work in the field of Medical Disposable Devices in the year 2012 , following their passion. Working with various organizations and multinationals world-wide has given FAB dominance in their work.

Prototyping demands minute and perfect quality designing and engineering, and FAB excels in the same. The fields of international regulatory

requirements, patent research, etc. are also considered.

Assembly and Testing:

We have our own Class 10000 Clean Room with a work force of 150 trained personnel covering an area of 30000 square feet, where we manufacture

and assemble all the medical disposable devices. Our Medical Device Assembly takes place with a perfect blend of skilled handwork and semi-automatic processes. We design and build jigs and fixtures to aid in the assembly of Medical Devices. Each assembly process is validated to

ensure quality.

We also have an in-house laboratory for conducting the testing of devices. Capabilities include physio-chemical, sterility, pyrogen, toxicity testing as per USP and ISO Standards.

All the manufacturing, assembling and testing process is carried out in a temperature controlled and FDA compliant environment.